herunterladen

Technical Note

TruStability

®

Pressure Sensor Liquid Media Compatibility

and Guidelines

Sensing and Control

BACKGROUND

TruStability

®

Pressure Sensors (HSC Series High Accuracy

and SSC Series Standard Accuracy) have an available

option that extends performance from non-corrosive, non-

ionic gases to non-corrosive, non-ionic liquids and

condensing humidity on the primary pressure port (Port 1).

The information in this Technical Note is intended to assist

end users in understanding the performance of this “liquid

media” option.

When using pressure sensors across a variety of liquid

media, it is necessary to ensure that the sensor is able to

operate with the desired liquid without adverse effects. To

ensure compatibility, it is important to consider all the

materials in the sensor with which the liquid will come into

contact.

Customers using the liquid media option should review the

product data sheets to understand the materials in the liquid

media’s path. Ultimately, it is up to the customer to

determine if the sensor is compatible with the liquid media

and is right for the application. Honeywell can assist in this

effort, utilizing our existing application knowledge and testing

experience.

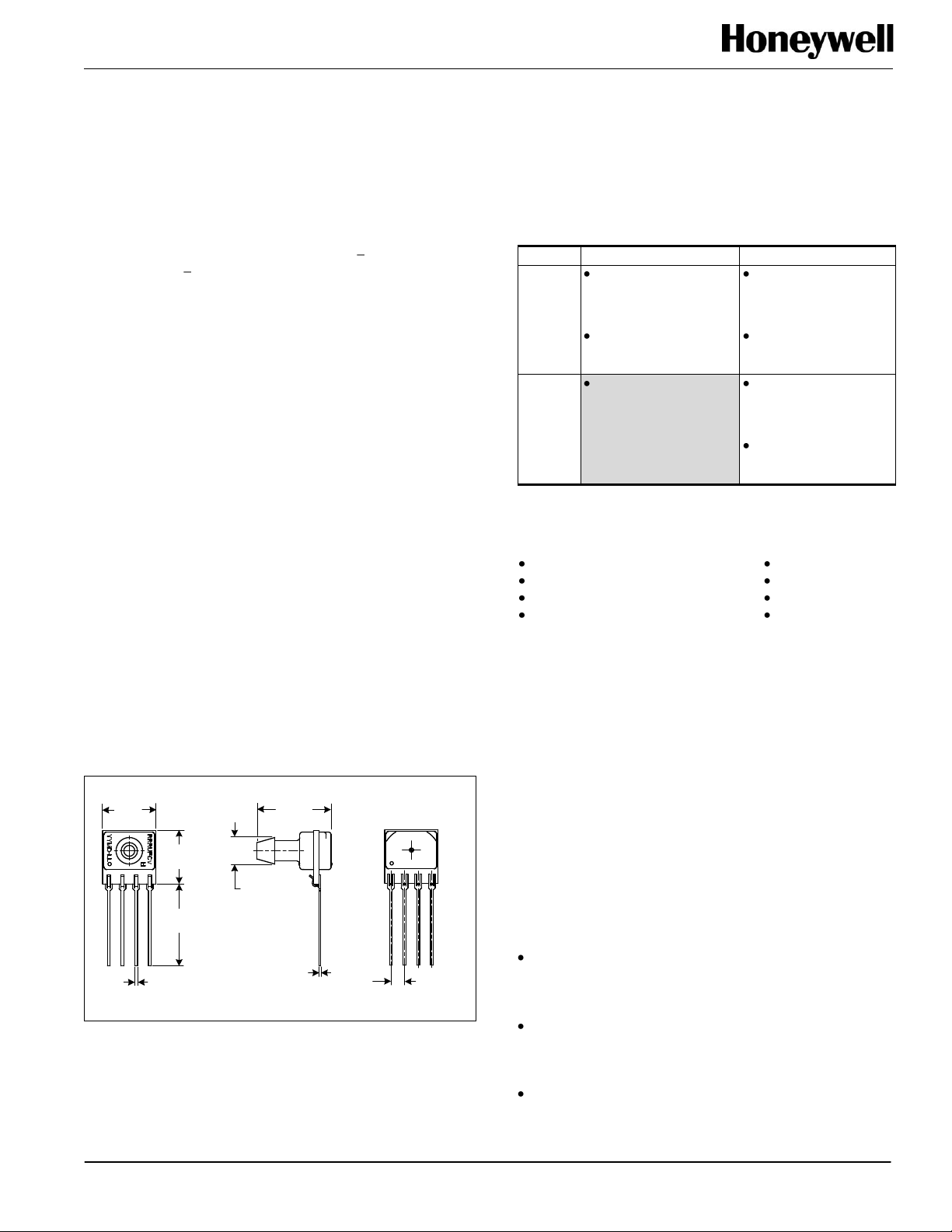

PRESSURE PORT DESCRIPTION

TruStability

®

Pressure Sensors have two pressure ports,

labeled Port 1 and Port 2, on the dimensional drawings in

the product data sheets. Port 1 is the primary pressure port

and Port 2 is the reference pressure port (see Figure 1).

Figure 1. SIP AN Port Configuration Dimensional Drawing

0,25

[0.010]

2,54 TYP.

[0.100]

PORT 1

1 2 3 4

10,0

[0.39]

4.93 DIA.

[0.194]

10,0

[0.39]

13,75

[0.541]

15,2

[0.60]

PORT 2

4X 0,51

[0.020]

PRESSURE PORT COMPATIBILITY

TruStability

®

products with the liquid media option have

additional protection applied to Port 1 to allow it to survive

exposure to condensing humidity and some liquids (see

Table 1).

Table 1. TruStability

®

Pressure Port Compatibility

Option

Port 1

Port 2

without

liquid

media

option

non-corrosive, non-

ionic media only

(such as air and dry

gases)

must not be exposed

to condensing

humidity

non-corrosive, non-

ionic media only

(such as air and dry

gases)

must not be exposed

to condensing

humidity

with

liquid

media

option

non-corrosive, non-

ionic liquids or gases

non-corrosive, non-

ionic media only

(such as air and dry

gases)

must not be exposed

to condensing

humidity

PORT 1 WETTED MATERIALS OF CONSTRUCTION

The following wetted materials of construction are exposed

materials in the media path:

High temperature polyamide

Silicone

Alumina ceramic

Silicon

Epoxy

Ceramic

Glass

Solder

The liquid media being used needs to be compatible with all

wetted materials used in the sensor construction (i.e., covers,

substrate, adhesives and electronic components). Even

though a liquid may be compatible initially, it is not

uncommon for some media to undergo chemical changes in

the application over time. If this is possible in the end user

application, the changed media also needs to be validated

as compatible with the wetted materials.

An example of this change is when a compatible gas, like

nitrogen dioxide (NO

2

), combines with high humidity to form

nitric acid (HNO

3

), which, at certain concentrations, will etch

the silicon sensor die and affect the sensor output. The

same thing may occur when water is present in combination

with NO

2

or other gases that create an incompatible working

liquid.

SENSOR PORT POSITIONING

Recommend that the sensor be positioned with Port 1

facing downwards; any particulates in the system are

less likely to enter and settle within the pressure sensor if

it is in this position.

Ensure liquid media contains no particulates. All

TruStability® sensors are dead-ended devices.

Particulates can accumulate inside the sensor, causing

damage or affecting sensor output.

Ensure liquid media does not create a residue when

dried; build-up inside the sensor may affect sensor output.

Rinsing of a dead-ended sensor is difficult and has

limited effectiveness for removing residue.

Verzeichnis