herunterladen

© Semiconductor Components Industries, LLC, 2014

December, 2014 − Rev. 1

1 Publication Order Number:

AND8353/D

AND8353/D

Implementing Cost

Effective and Robust Power

Factor Correction with the

NCP1607

Introduction

The NCP1607 is a voltage mode power factor correction

(PFC) controller designed to drive cost-effective converters

to meet input line harmonic regulations. The device operates

in Critical Conduction Mode (CRM) for optimal

performance in applications up to about 300 W. Its voltage

mode scheme enables it to obtain unity power factor without

the need for a line sensing network. The output voltage is

accurately controlled with a built in high precision error

amplifier. The controller also implements a comprehensive

array of safety features for robust designs.

This application note describes the design and

implementation of a 400 V, 100 W, CRM Boost PFC

converter using the NCP1607. The converter exhibits high

power factor, low standby power dissipation, high active

mode efficiency, and a variety of protection features.

The Need for PFC

Most electronic ballasts and switching power supplies use

a diode bridge rectifier and a bulk storage capacitor to

produce a dc voltage from the utility ac line. This produces

a non-sinusoidal current draw and increases the demand on

the power delivery infrastructure. Government regulations

and utility requirements often necessitate control over line

current harmonic content.

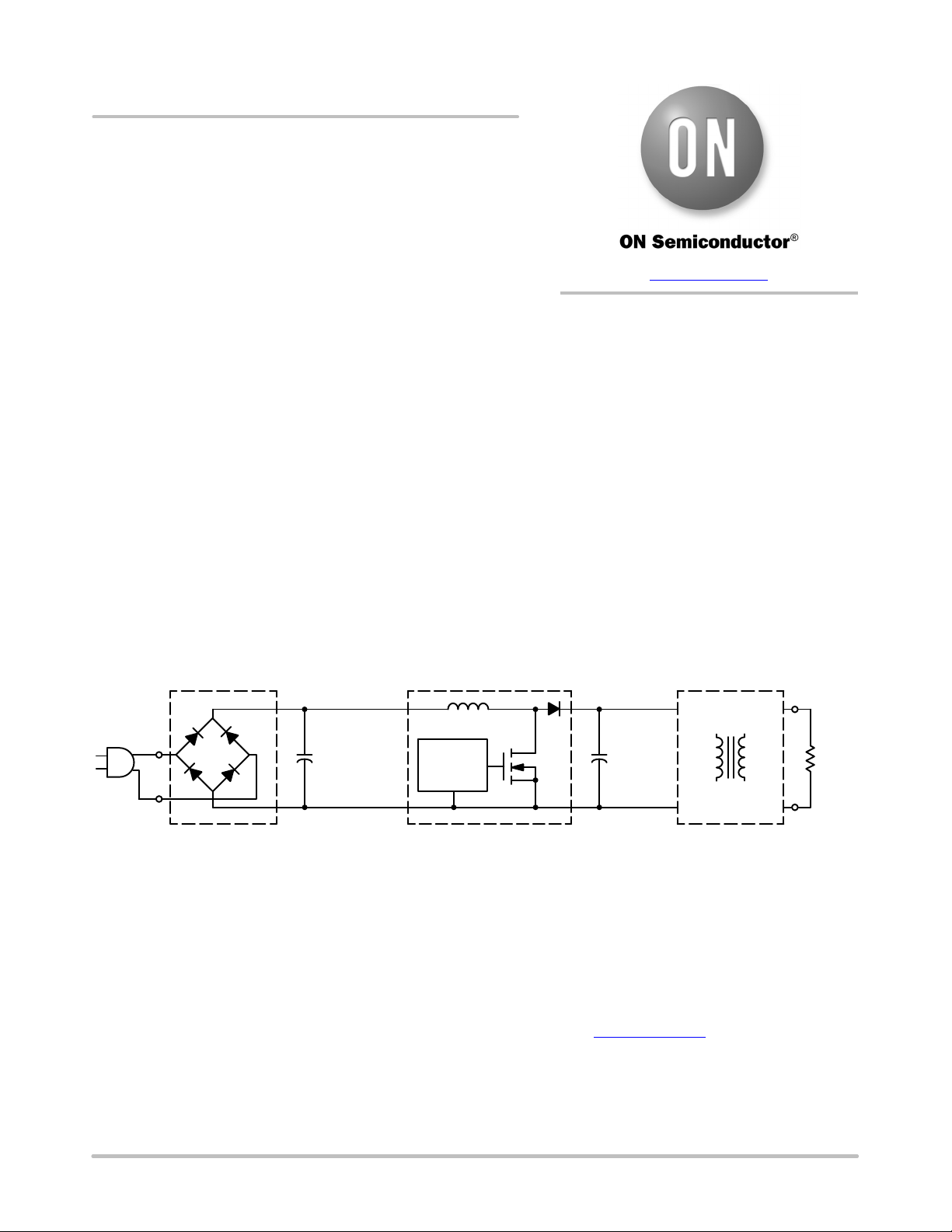

Active PFC circuits have become the most popular way to

meet these harmonic content requirements. They consist of

inserting a PFC pre-regulator between the rectifier bridge

and the bulk capacitor (Figure 1). The boost (or step-up)

converter is the most popular topology for active power

factor correction. With the proper control, it can be made to

produce a constant output voltage while maintaining

a sinusoidal input current from the line.

Figure 1. Active PFC Stage with the NCP1607

Rectifiers

+

AC Line

High

Frequency

Bypass

Capacitor

NCP1607

PFC Preconverter

Converter

Load

+

Bulk

Storage

Capacitor

Basic Operation of a CRM Boost Converter

For medium power (< 300 W) applications, critical

conduction mode (CRM) is the preferred control method.

Critical conduction mode occurs at the boundary between

discontinuous conduction mode (DCM) and continuous

conduction mode (CCM). In CRM, the next driver on time

is initiated when the boost inductor current reaches zero.

Hence, CRM combines the lower peak currents of CCM

operation with the zero current switching of DCM

operation. This control method causes the frequency to vary

with the line input voltage and the output load. The operation

and waveforms of a PFC boost converter are illustrated in

Figure 2. For detailed information on the operation of

a CRM Boost Converter for PFC applications, please refer

to AND8123 at www.onsemi.com

.

APPLICATION NOTE

www.onsemi.com

Verzeichnis